HeronTrack 1B

€53,000

total amount raised in round

5300%

- Eligible for a tax reduction

Campaign Closed

DISCLAIMER

Every investment decision must be based on an examination of an exhaustive set of information provided by the entrepreneur on their online profile. Spreds only proceeds to a limited verification of this information and does not control the investment opportunity within this company. Spreds did not verify the extent to which the business plan is deemed realistic and does not intervene in determining the final terms of the investment, including the retained maximum valuation. Spreds will align itself with the financial terms negotiated with the co-investor(s).

Description

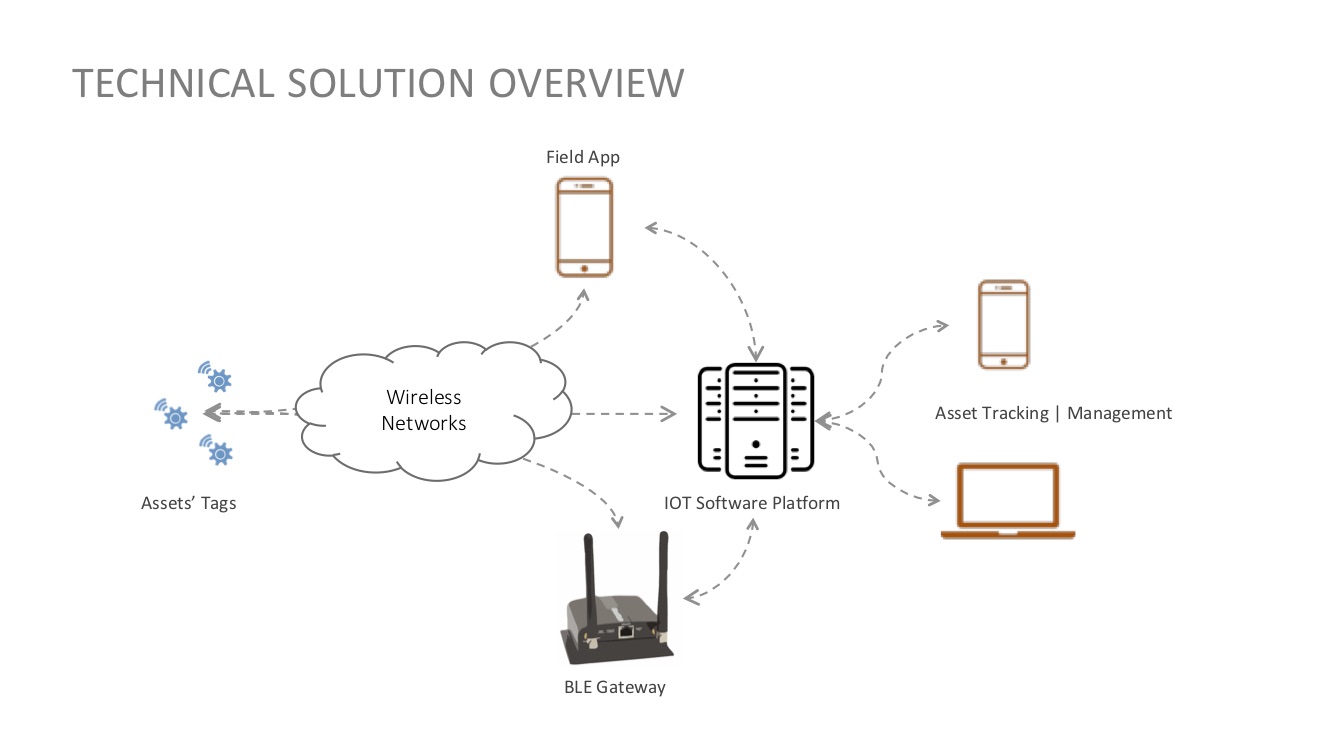

HeronTrack (Heron means "tool" in ancient Greek) is a solution for the management of small equipment and equipment used by construction workers or technical services. We have developed a tag (smart sensor) to be installed on or in the tool, such as a ladder, a compressor, a grinding wheel, etc. The tag communicates via Bluetooth (BLE) with a smartphone or gateway (a station that detects the presence of tools).

The smartphone with our mobile application (iOS and Android) allows the employee in the field to detect the tools around him/her and to link the GPS position of the smartphone to the tool, so that this information together with the ID number of the tag (UID) can be sent to our platform (based on the IOT Hub). This way, the information is available in the form of reports or visual information on the tagged tool's map.

The gateway is more likely to be installed at fixed locations such as the depot to detect which tools are in the depot / at the location. On the other hand, if there are no smartphone or other Bluetooth readers in the area, the tag also communicates via LoRa over the Proximus public network to display geolocation via triangulation (antennas) and thus the location of the tool, for example, even if no one is on the construction site.

Via the web- and mobile solution it is possible to trace the tools, it is also possible to manage the inventory autonomously (without human intervention) and offers a solution for the inspections (which is mandatory in Belgium) of the equipment and the registration in the digital logbook, to show the good condition of the tools.Users always have insight into the availability of the tool, but also the location, the state, the user, the daily costs ...

The smartphone with our mobile application (iOS and Android) allows the employee in the field to detect the tools around him/her and to link the GPS position of the smartphone to the tool, so that this information together with the ID number of the tag (UID) can be sent to our platform (based on the IOT Hub). This way, the information is available in the form of reports or visual information on the tagged tool's map.

The gateway is more likely to be installed at fixed locations such as the depot to detect which tools are in the depot / at the location. On the other hand, if there are no smartphone or other Bluetooth readers in the area, the tag also communicates via LoRa over the Proximus public network to display geolocation via triangulation (antennas) and thus the location of the tool, for example, even if no one is on the construction site.

Via the web- and mobile solution it is possible to trace the tools, it is also possible to manage the inventory autonomously (without human intervention) and offers a solution for the inspections (which is mandatory in Belgium) of the equipment and the registration in the digital logbook, to show the good condition of the tools.Users always have insight into the availability of the tool, but also the location, the state, the user, the daily costs ...

Problem

The needs are multiple:

- theft prevention

- management of equipment: inventory

- tool inspection management

- cost control

To prevent theft, the Construction Confederation published an article in 2012, stating that tools are often stolen on construction sites. One in two companies has 1 to 3 thefts per year. The confederation estimates that more than 50 million euros worth of equipment is stolen every year. This requires a solution!

For inventory management: it is very difficult nowadays for construction companies to make inventories because the vehicles have to be permanently on site due to productivity, deadlines and efficiency. As a result, the inventory is usually carried out once a year during the construction holidays. It is during this check that broken tools are found that were never reported or that purchases were made of tools that were not needed. It is necessary to have an overview of equipment and tools at all times in order to make the right decisions.

Management of inspections: it is mandatory to be able to show that the equipment used is in good condition for accident prevention and insurance. There are regulations for preventive and periodic checks, depending on the type of equipment. This management is also difficult because the personnel responsible for managing the tools or the technician who needs to go to the inspection lose a lot of time to locate them. Without having a real-time overview of where the tool to be inspected is located, it is very cumbersome to schedule an inspection and a lot of time is lost to find the tool in question. After the inspection, the information must be kept in case of a check to prove that the rules have been applied.

Cost control: as explained in the item "inventory", a good inventory can be used to check the purchase of tools that are not necessary. Moreover, it is always necessary to allocate the costs of using the tool to a site and therefore a daily entry of the cost of small equipment can be registered.

Today, many companies in the construction sector have IT solutions for vehicle management, man and machine hours, projects, invoicing, but they still work with paper booklets for managing small equipment and planning maintenance and inspections. There is a need for digitisation of this management and therefore an IT tool for tracing small equipment!

- theft prevention

- management of equipment: inventory

- tool inspection management

- cost control

To prevent theft, the Construction Confederation published an article in 2012, stating that tools are often stolen on construction sites. One in two companies has 1 to 3 thefts per year. The confederation estimates that more than 50 million euros worth of equipment is stolen every year. This requires a solution!

For inventory management: it is very difficult nowadays for construction companies to make inventories because the vehicles have to be permanently on site due to productivity, deadlines and efficiency. As a result, the inventory is usually carried out once a year during the construction holidays. It is during this check that broken tools are found that were never reported or that purchases were made of tools that were not needed. It is necessary to have an overview of equipment and tools at all times in order to make the right decisions.

Management of inspections: it is mandatory to be able to show that the equipment used is in good condition for accident prevention and insurance. There are regulations for preventive and periodic checks, depending on the type of equipment. This management is also difficult because the personnel responsible for managing the tools or the technician who needs to go to the inspection lose a lot of time to locate them. Without having a real-time overview of where the tool to be inspected is located, it is very cumbersome to schedule an inspection and a lot of time is lost to find the tool in question. After the inspection, the information must be kept in case of a check to prove that the rules have been applied.

Cost control: as explained in the item "inventory", a good inventory can be used to check the purchase of tools that are not necessary. Moreover, it is always necessary to allocate the costs of using the tool to a site and therefore a daily entry of the cost of small equipment can be registered.

Today, many companies in the construction sector have IT solutions for vehicle management, man and machine hours, projects, invoicing, but they still work with paper booklets for managing small equipment and planning maintenance and inspections. There is a need for digitisation of this management and therefore an IT tool for tracing small equipment!

Idea

Our small equipment management solution offers construction companies an answer to the four most important needs:

- inventory: via our mobile application the follow-up is in real-time and automatic. The worker should not be concerned with scanning all the equipment; the application does it for him. It regularly checks for tools in the vicinity of the worker (15-meter radius) and even the non-company tools are read. These are sent to the platform for identification and shared with the owner

of the respective tools. The warehouse manager can see on a map and in a list where the material is located and who uses it.

- inspection management: the logical follow-up based on the inventory is a permanent view of the tool, making it easier to schedule an inspection and send the GPS coordinates of the tool to the technician who is to perform the inspection. The registration of the inspection can be done with the application and the status can be changed to "inspected" with the information by who, what time, which day and where.

- cost control: with a better view of the use of the equipment and their availability, it is possible to calculate material costs per yard per day (rent), but also to check whether the tool is productive and therefore used optimally. Workers can no longer withhold the tool while waiting for another yard to start in a few weeks, the warehouse manager sees if the tool is needed for a particular worker and can, therefore, make it available to another team instead of at the last minute rent the same tool or even buy a new tool.

- anti-theft: via the integrated GPS and LoRa communication, it is possible in case of theft to activate an anti-theft configuration that is sent to the tag to activate the GPS and to send a position every 5 minutes to quickly get the tool to recover.

Our solution integrates all BLE (Bluetooth) tags on the market so that no one is obliged to replace existing equipment such as that of Hilti, but we give an extra dimension with our own tag (BLE + LoRa) that offers a complete solution for small equipment and the more expensive one's equipment that must also be secured via an intuitive platform and mobile applications.

- inventory: via our mobile application the follow-up is in real-time and automatic. The worker should not be concerned with scanning all the equipment; the application does it for him. It regularly checks for tools in the vicinity of the worker (15-meter radius) and even the non-company tools are read. These are sent to the platform for identification and shared with the owner

of the respective tools. The warehouse manager can see on a map and in a list where the material is located and who uses it.

- inspection management: the logical follow-up based on the inventory is a permanent view of the tool, making it easier to schedule an inspection and send the GPS coordinates of the tool to the technician who is to perform the inspection. The registration of the inspection can be done with the application and the status can be changed to "inspected" with the information by who, what time, which day and where.

- cost control: with a better view of the use of the equipment and their availability, it is possible to calculate material costs per yard per day (rent), but also to check whether the tool is productive and therefore used optimally. Workers can no longer withhold the tool while waiting for another yard to start in a few weeks, the warehouse manager sees if the tool is needed for a particular worker and can, therefore, make it available to another team instead of at the last minute rent the same tool or even buy a new tool.

- anti-theft: via the integrated GPS and LoRa communication, it is possible in case of theft to activate an anti-theft configuration that is sent to the tag to activate the GPS and to send a position every 5 minutes to quickly get the tool to recover.

Our solution integrates all BLE (Bluetooth) tags on the market so that no one is obliged to replace existing equipment such as that of Hilti, but we give an extra dimension with our own tag (BLE + LoRa) that offers a complete solution for small equipment and the more expensive one's equipment that must also be secured via an intuitive platform and mobile applications.

Marketing strategy

The strategy starts with the website and SEO via Google (AdWords).

Every 2 months we send a newsletter to our database of construction companies, which has been regularly inspected during the last 10 years and of which more than 300 companies are already active as customers through other solutions.

The news is also shared with links to the website on the various social media: Facebook, Twitter and LinkedIn.

In parallel, 4 direct mailings are planned until the end of 2019, followed by a call (call center: Telmacom) from the database used for the mailing.

Our personal network of construction companies will be visited proactively to sell the test kit with 5 tags + application and in this way optimise visits.

But most importantly: companies no longer want promises, but a working solution and with the kit of 199.00 EUR they can test the solution directly on site and, if convinced, order online.

Every 2 months we send a newsletter to our database of construction companies, which has been regularly inspected during the last 10 years and of which more than 300 companies are already active as customers through other solutions.

The news is also shared with links to the website on the various social media: Facebook, Twitter and LinkedIn.

In parallel, 4 direct mailings are planned until the end of 2019, followed by a call (call center: Telmacom) from the database used for the mailing.

Our personal network of construction companies will be visited proactively to sell the test kit with 5 tags + application and in this way optimise visits.

But most importantly: companies no longer want promises, but a working solution and with the kit of 199.00 EUR they can test the solution directly on site and, if convinced, order online.

Distribution strategy

Online order (via website) of the starter kit + free trial version if already equipped with BLE tags.

A packaging company supplies the material (+ tag assigned to the customer's account) and the support team will activate the account.

The CSM monitors the installation and it provides a paid training online.

A packaging company supplies the material (+ tag assigned to the customer's account) and the support team will activate the account.

The CSM monitors the installation and it provides a paid training online.

Internationalisation strategy

No exports in 2019, but we already have a few discussions with potential partners for the Netherlands and Germany.

Intellectual Property

- co-development of the ConstruTag sensor with IOT Factory.

- development of "HeronTrack" management software based on Microsoft's IOT Hub platform.

- development of the mobile application "HeronTrack" on iPhone and Android in native development for better performance.

- development of the web application "HeronTrack" on React JS.

- brand, website (mobile / PC) and all associated means of communication.

- development of "HeronTrack" management software based on Microsoft's IOT Hub platform.

- development of the mobile application "HeronTrack" on iPhone and Android in native development for better performance.

- development of the web application "HeronTrack" on React JS.

- brand, website (mobile / PC) and all associated means of communication.

Major contracts

Supplier contract with Codit Microsoft partner for the development of the IOT platform. Development based on Microsoft technology such as Azot's IOT Hub and Cloud Services, and another supplier contract with Epseelon SPRL for the development of user interfaces (web and mobile). Finally, the hardware contract with IOT Factory.

Main partners

Digital Attraxion is a digital startup accelerator, and we have been selected for their MoveUp program. Digital Attraxion’s Move Up Program is an acceleration program of 20 weeks based in Hainaut. For startups from everywhere who are looking to launch on the European market in the Digital Transformation of Industry also known as Industry 4.0. The program proposes an introduction to clients and investors, a European road map for commercialisation, funds, access to a co-working place, days of coaching and workshops/training.

Codit (the Microsoft platform section) has +180 employees in 7 countries (Belgium, France, Portugal, the Netherlands, United Kingdom, Malta and Switzerland). Of these 180 employees, 30 are specialised in development on Azure cloud-native application and IOT. All these employees have the necessary expertise based on projects and/or training and/or certifications.

Codit is a Microsoft Gold partner for Application Integration, Application Development and Cloud; and Silver partner for Data Analytics.

IOT Factory (the hardware part: tag and gateway): a team that likes to create. IOT Factory is a European company based in Brussels, dedicated to the internet of things. Founded by veterans of the telematics and mobile applications' industry, with over 15 years of experience on the internet of things, they want to make IOT simple and affordable through robust and reusable software components, easy to assemble and adapt for IOT projects and product implementations.

The IOT Factory team is composed of: back-end, front-end (web/mobile), graphics designers ... Responsible for the development of the IOT Factory platform, as well as helping their customers and Startup partners to complete their projects to develop.

Codit (the Microsoft platform section) has +180 employees in 7 countries (Belgium, France, Portugal, the Netherlands, United Kingdom, Malta and Switzerland). Of these 180 employees, 30 are specialised in development on Azure cloud-native application and IOT. All these employees have the necessary expertise based on projects and/or training and/or certifications.

Codit is a Microsoft Gold partner for Application Integration, Application Development and Cloud; and Silver partner for Data Analytics.

IOT Factory (the hardware part: tag and gateway): a team that likes to create. IOT Factory is a European company based in Brussels, dedicated to the internet of things. Founded by veterans of the telematics and mobile applications' industry, with over 15 years of experience on the internet of things, they want to make IOT simple and affordable through robust and reusable software components, easy to assemble and adapt for IOT projects and product implementations.

The IOT Factory team is composed of: back-end, front-end (web/mobile), graphics designers ... Responsible for the development of the IOT Factory platform, as well as helping their customers and Startup partners to complete their projects to develop.